surface grinding machine pdf

While the wheel is spinning lower the grinding wheel down in the Z direction until it makes a small plume of dust. It utilizes a table that moves on a horizontal plane and a grinding wheel that moves along a vertical axis.

This machine may be similar to a milling machine used mainly to grind flat surface.

. Prayosha Enterprise is the largest manufacturer of high exactness surface grinding machines in IndiaWe are reputed manufacturer and exporter of Surface grinding machine. Surface Grinding Machine is a machine in which a grinding wheel is used as a cutting tool for removing the material from the surface of the workpiece. Table size 225 450 mm 300 600 mm 2 Max.

Longitudinal travel 500 mm 650 mm 3 Max. Rotary Table Grinding Machines. Ask shop staff to demonstrate proper use of this tool.

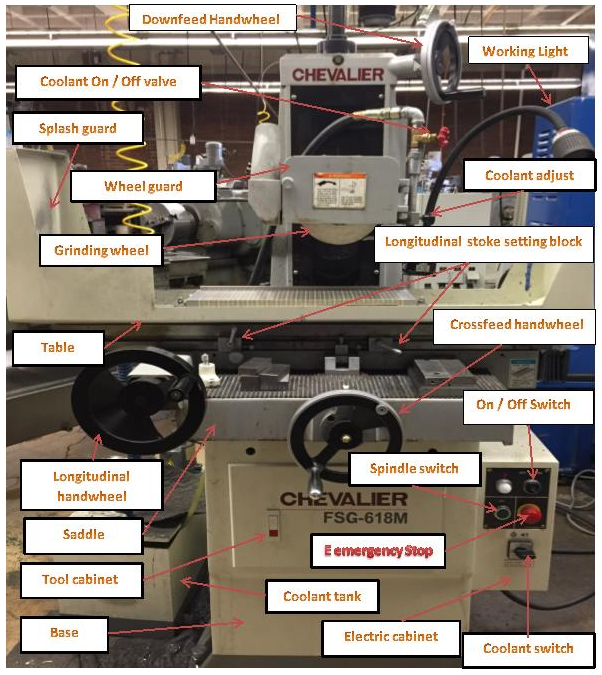

Chevalier offers a one year limited-warranty that includes parts for mechanical and electrical components. Voltage 220-380 Volt v Supply Ability. About This Machine Capabilities This 6 x 18 Surface Grinder allows you to smooth the surface of metallic workpieces.

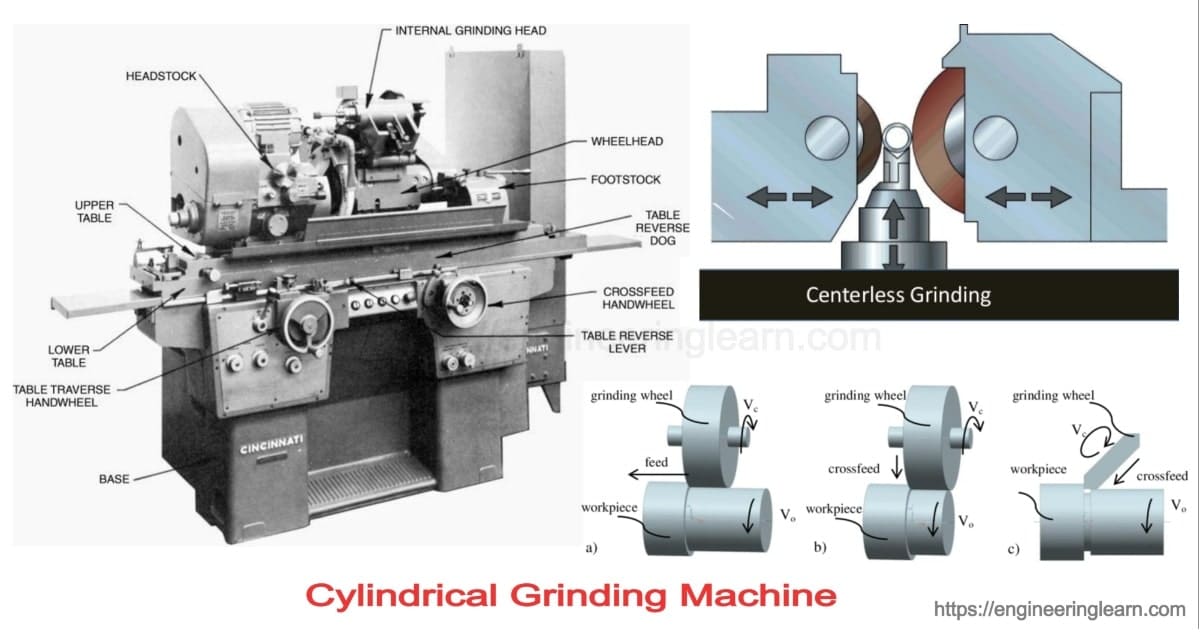

Great savings from in-situ grinding and milling. Surface Grinding Machine Supplier. Cylindrical grinding machine This machine is used to produce external cylindrical surface.

Standard operating range diameter 320700 mm. The workpiece is supported on a rectangular table which moves back and forth and reciprocates beneath the grinding wheel. Surface.

Cross traverse 225 mm 305 mm 4 Max. My outlay was under 6 including the cost of welding. Eliminates and prevents water and gas leakages.

Broadly there are three different types of cylindrical grinding machine as follows. Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the dresser. It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece.

Surfaces may be straight tapered steps or profiled. Mitsui surface grinder preventative maintenance program for hand feed models 6x12 6x18 8x18 hydraulic machines quoted separately remove table clean bearings and ways adjust table movement with cable check lubricator and lubrication system. Types of surface grinding machines Tool and cutter grinder In grinding tools by hand a bench or pedastal type of grinder is used.

Pdf 7 MB BLOHM PLANOMAT Product Brochure Download. Turn the machine off after making contact with the dresser. Advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finish as well as high material removal rate can be achieved even on an unhardened material.

Are transmitted to the. Turn the machine on again. For grinding of sealing surfaces between cylinder head and cylinder liner and between cylinder liner and engine frame on medium bore diesel engines.

A Surface grinding machine b Cylindrical grinding machine c Internal grinding machine d Tool and cutter grinding machine 291 Surface grinding machine. It is used to produce finished parts and accurate dimensions. Abrasive wheel machinery shall not be operated without the appropriate guards in place.

Our main aim is to be the leader in every market we serve. Surface grinding machines for flat. Grinding Safety Guidelines 1.

Replace oil metering unit at crossfeed screw replace or clean crossfeed drain line secure drain hoses. Universal cylindrical surface grinder 3. F All machining was done on a ML7 lathe excepting the shaping of column and surface grinding.

The tool is hand held and moved across the face of the wheel continually to avoid excessive grinding in one spot. Horizontal spindle and reciprocating table type 2. Entire machine is fabricated in steel picked from scrap.

Tool rests on bench or pedestal grinders shall be set no more than 116 inch from the wheel. Surface Grinding Machines CPM. For better surface finishing better accuracy or close tolerances For hardened materials Very little metal removal Cutters.

In such cases it is impossible to achieve good surface finishes as the vibrations from the milling machine or jerks from the reversal of the shaper stroke etc. Precision grinding removes negligible amount of metal. 20 Unit Per Month.

Grinding machines are often found between milling shaping drilling and even. It is also called an abrasive machining process where abrasives are placed on the surface and corners of the grinding wheel so as to do the finishing process with much more accuracy. To continuously offer reliable high-performance precision surface grinders.

Centreless cylindrical surface. Special training is required before using the surface grinder. Depending on the geometry of workpiece and the position at which workpiece is to be grind it can be categorize as external grinding internal grinding surface grinding form grinding and centreless grinding.

Our registered trade mark which is renowned name in the field of Surface Grinders. Slotting machines without any thought of the consequences of such planning. Working Principle of Surface Grinding Machine.

Hydraulic Surface Grinding Machine Technical Specifications ID Model Aarti H-1 Aarti H-2 Capacity 1 Max. The only parts purchased were pulleys tw o Myford gear wheels 30 and 60 teeth two bearing blocks and elevating screw hand-wheel. Pdf 7 MB BLOHM PROFIMAT MT Product Brochure Download.

The grinding machine are often found between millingshapingdrilling and even slotting machinewithout any thought of the cons equences of such planningIn such casesit is impossible to achieve good surface finishesas the vibrations from the milling machine or jerks from the reversal of the shaper strokeetcare transmitted to the grinding. Reciprocating surface grinding machines generally have horizontal wheel spindles and. Types of Grinding wheels.

Surface Grinding Machine uses a rotating abrasive wheel to remove the material from the surface of the workpiece to create a flat surface with a high surface finish. Fayed Page 22 Applications. CNC Or Not Normal.

The surface grinding machine is used for grinding flat surfaces. 15000000 - 150000000 INRUnit. A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial.

Generally the grinding is finishing operation to show the high surface quality accuracy of the shape and dimension. For sharpening miscellananeus cutters a universal type grinder is used. By mounting a workpiece to the table then moving the table and the grinding wheel during.

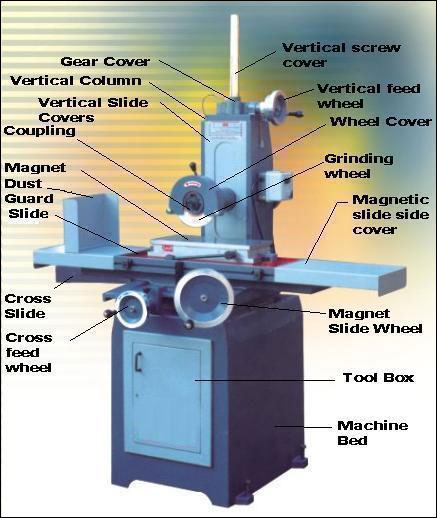

The bulk grinding wheel workpiece interaction as given in Figure 2 can be divided into the following. Conventional grinding machines can be broadly classified as. The grinding wheel revolves on a spindle and the workpiece is mounted on a reciprocating table.

The high-precision FSG-3A series surface grinder has recently improved the control panel with easy to read LED numerals. Type Surface Grinding Machine. Study of Machine Tools Grinding Machines Page 2 424 Surface grinding machines Surface grinding machines are employed to finish plain or flat surfaces horizontally vertically or at any angle.

Plain centre type cylindrical grinder 2. There are four different types of surface grinders.

Chapter 5 Surface Grinder Manufacturing Processes 4 5

Hydraulic Circuit For Surface Grinding Machine Explained In Details Engineering Arena

14 Types Of Grinding Machines Working Diagram Pdf

14 Types Of Grinding Machines Working Diagram Pdf

Guru Arjan Machine Tools Surface Grinder Machine Surface Grinding Machine Surface Grinding Machine Manufacturer

Parts And Functions Of Grinding Machine Grinding Machine Grinding Machine Types

Muhammad Musa Muslimmuhammad313 Profile Pinterest

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

14 Types Of Grinding Machines Working Diagram Pdf

Horizontal Spindle Grinding Operations A Traverse Grinding And B Download Scientific Diagram

Manual Surface Grinder Wheel Head Moving Surface Grinders Manufacturer From Faridabad

Grinding Machine Parts And Functions Mechanical Walkins

Une Maison Confortable Pour Vous Parts Of Surface Grinding Machine Pdf

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

Grinding Machine Types Parts Working Operations With Pdf

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Cylindrical Grinding Machine Types Process Working Principle Engineering Learn